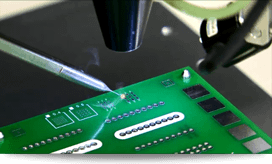

Soldering is a supremely useful skill to have in your repertoire. It's a prerequisite for fixing or maintaining almost anything electrical or electronic, from major appliances to tiny cell phones and MP3 players. All that's required is the appropriate soldering iron for the job, a steady hand, and the patience to do it over again until you've mastered the process. Soldering irons offer a wide range of tips, temperatures and other features, so selecting one requires some thought.

Tips

If you solder on even an occasional basis, it's worth investing in a few basic accessories. A desoldering tool can speed repairs, and make it easier for you to correct mistakes as you learn. Purchase solder in two or three diameters, so you'll have fine solder for fine work and larger solder for coarse work. Clip-on heat sinks can protect delicate components while you work nearby, and adjustable clamps can provide additional "helping hands" to hold things in place while you work.

Warnings

Soldering irons can cause serious burns if they're handled carelessly or dropped, and they have the potential to cause fires. Purchase a heatproof rest for your iron, or have a designated place to set it down while you work.

Always solder in a well-ventilated area, and avoid inhaling the fumes. Most types of solder contain lead, and the rosin core inside the solder can also create toxic fumes.